Plywood Size Comparison: Which Sheet Size Is Best for Your Application?

If you are choosing the appropriate lumber for your construction furniture, or industrial projects It is essential to think about both the plywood size and the types of wood that are used. Plywood comes in standard sizes and thicknesses that permit builders and designers to choose the right panel for their application.

Dimensions of the standard plywood

Plywood is available in a range of standard sizes to meet the varied requirements of furniture construction, and industrial applications. The most popular is 4×8 Plywood (1220 mm by 2440 mm) It has a variety of uses, including flooring, cabinetry, roofs, and walls. The standard size was designed to accommodate typical framing and reduce waste and speeding up installation.

In addition to the popular 4×8 boards, many manufacturers have larger size panels, like 4×9 feet, or 5×10 feet, for jobs that require less seams, greater coverage or other special applications such as concrete formwork or exterior signage. Vinawood, for example, provides custom-sized thickness and plywoods to meet specific project specifications. A proper size of plywood is essential for an entire project’s structural strength, efficiency and finish.

Choosing the right plywood size

What determines the right size the plywood?

- Applications: Floors and furniture, walls or concrete forming

- Panels that are thick to satisfy structural requirements

- Use exterior-grade plywood to protect against the weather

Vinawood provides flexible options for projects that require specific dimensions or designs. The solutions are adapted for international markets and the domestic market.

Vinawood is a leading manufacturer of high-quality products made of plywood

Vinawood is a leading Vietnamese plywood manufacturer, offering a wide range of high-quality, certified plywood products of various sizes and specifications that are suitable for industrial, construction, and interior applications. Vinawood has more than thirty years’ experience in the production of plywood and is committed to providing durable, environmentally-friendly and high-performance solutions.

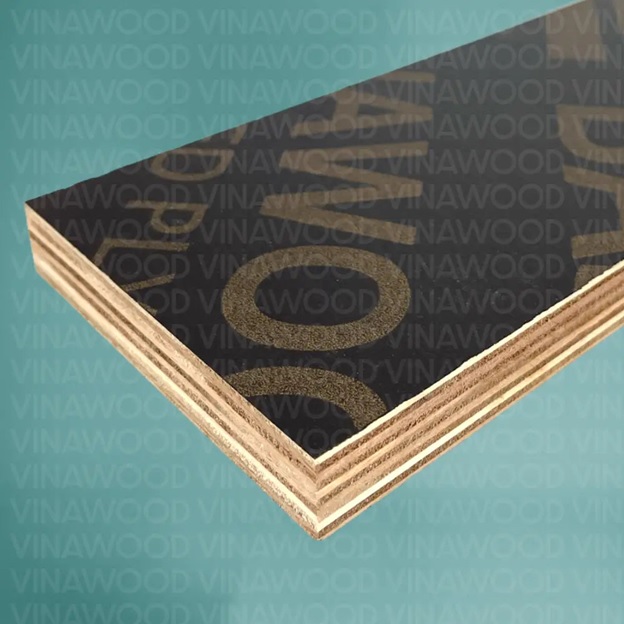

Vinawood has a broad range of items, which include Film Faced Plywood (MDO), HDO (Marine Plywood), Commercial Plywood (Vinawood) Phenolic/PPE coated panel (Multi-purpose Panels) Laminated Veneer Lumbers (LVL) and as well in a range of dimensions and different thicknesses.

Excellence in product across all the various categories

Formply is a film faced plywood made of a plantation wood veneer. It is bonded with adhesives that were developed by the firm. This results in an item with exceptional durability and resistance to water. These panels have a smooth surface and are recyclable, and may be used for shuttering and concrete formwork.

MDO Plywood and HDO Plywood have been designed to provide both an attractive and practical performance in construction. The panels have a sleek appearance and a better resistance to the elements which makes them perfect for projects that demand both appearance and longevity.

Marine Plywood has a hardwood base and is water-proof. It is durable even in wet environments. Commercial Plywood is an affordable alternative for furniture, interior design and cabinetry.

Development of markets and global reach

Since 2005, Vinawood has contributed significantly to expanding Vietnam’s plywood exports, with its volume accounting for 5-15 percent of Vietnam’s overall plywood exports, which are to key market segments like South Korea and Japan. A reputable supplier within the Asia-Pacific region, Vinawood expanded to the U.S., Mexico, Turkey as well as the U.A.E. Vinawood launched its domestic sales department in the year 2014 following the establishment of its first branch in 2012. It was designed to address the ever-growing needs of Vietnam for trade and construction.

Vinawood is able to export 60% of their products to China, the U.S.A., U.A.E. South Korea, Japan and Malaysia. A further 40% is for domestic markets. Vinawood’s track record of reliability and innovativeness has helped it earn a spot in Vietnam Report’s Top 500 Fastest Growing Companies for 2015.

Commitment to quality and sustainability

Vinawood has been awarded a variety of prestigious international certificates, including ISO 9001 for quality management and FSC-COC, EPA TSCA Title IV, for low formaldehyde emission, CE Marking EN13986 for EU Safety Regulation compliance, in addition to Korea’s KS Mark. These certificates confirm Vinawood’s commitment towards the environment and compliance with regulations with international markets. Vinawood also has in-house advanced testing labs to ensure the highest quality and a reject rate less than 1,4%. Vinawood is able to verify, prior to the plywood is delivered to customers, that it meets strict performance and safety requirements.

A innovator in plywood manufacturing exporting and manufacturing, Vinawood continues to drive high-quality products through high-quality assurance and sustainable practices, serving as an ideal partner to professionals in woodworking and construction all over the world.

For more information about Vinawood’s products and quality commitment, please visit the official website at https://vinawoodltd.com/

- Email: info@vinawoodltd.com

- Tel: +84-83-333-2333