If the earlier facts Of food packaging supplies are noticed, then those different containers used to transport products originally, have nowadays taken a back seat. When contemplating the sort of shipping devices used before, the principal focus stood on the company’s viewpoint. As a matter of fact, till the end of 19th century, generally all dispatch processing techniques used simple materials to transport their products to the market

place. Those containers were made from clay, wood or bamboo.

place. Those containers were made from clay, wood or bamboo.

Then in the 20th Century there was a radical shift from the materials used for food packaging as the majority of them were created from glass, paper and metals. What is more, another development followed as PETE (Polyethylene Terephthalate) substance came to the market. This flexible plastic conveniently made bulk quantity of meals available for supply to customers in these PETE containers. The advantage was that the Polyethylene might be easily stamped or molded in almost any possible shape. Additionally, it was cheap to produce, thereby making it a economical packaging alternative for foods. However, as a result of rising environmental safety awareness nowadays, this alternative has made clients more attracted to eco friendly packaging solutions caused by providers.

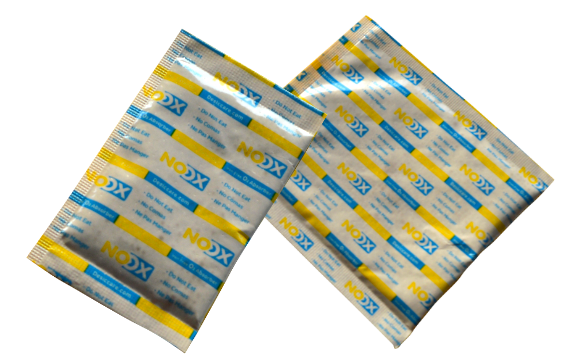

oxygen absorber packet is Pivotal in conserving food throughout the whole distribution chain. Otherwise, various food processing risks can lead to contamination because of direct contact with chemical, biological or physical contaminants. Nonetheless, in the last few years, novel food packaging concepts and techniques have improved the shelf life of various foods. Therefore, these measures have improved quality, security and sustainability to the marketplace. Such advancements also have aided to drinks, pharmaceutical drugs, and other perishable products to be fitter for sale and consumption.

Through the research Of material scientists, microbiologists and food chemists, the value of preserving shelf life through food packaging is principally linked to the packaging representative. This is the reason the PETE technology has greatly upgrading the packaging sector recently.

Few basic functions of Food Packaging

Barrier protection

Ideal food packaging Protects the barrier from water vapor, oxygen, dust, etc. Permeation is the critical element when it comes to design. Food packaging could include oxygen absorbers, desiccants to prolong the product shelf life. A climate controlled air is primary for some food packages; this retains the products clean, fresh and clean.

Physical protection

It may require Compression, shock temperature and vibration when enclosed in single bundle.

Agglomeration

Some small items are Grouped together in single bundle for efficient handling. Powders, granular fluids or materials need containment.

Kinds of Food Packaging

Food Packaging is Essential to maintain the quality of the perishable products during transit or for prolonged use. These types of packaging are clarified below:

- Primary packaging Contains the main package where the food is stored for processing.

- Secondary packaging Holds many main packages in 1 box that is completely wrapped.

- Tertiary packaging Conglomerates all secondary bundles in 1 pallet.

Some special packaging containers combine diverse technologies to have maximum durability and protection.